You’ve installed security cameras and alarm systems. You keep the doors locked. You have a security guard. But what else can you do to protect your property and address your building’s unique security concerns?

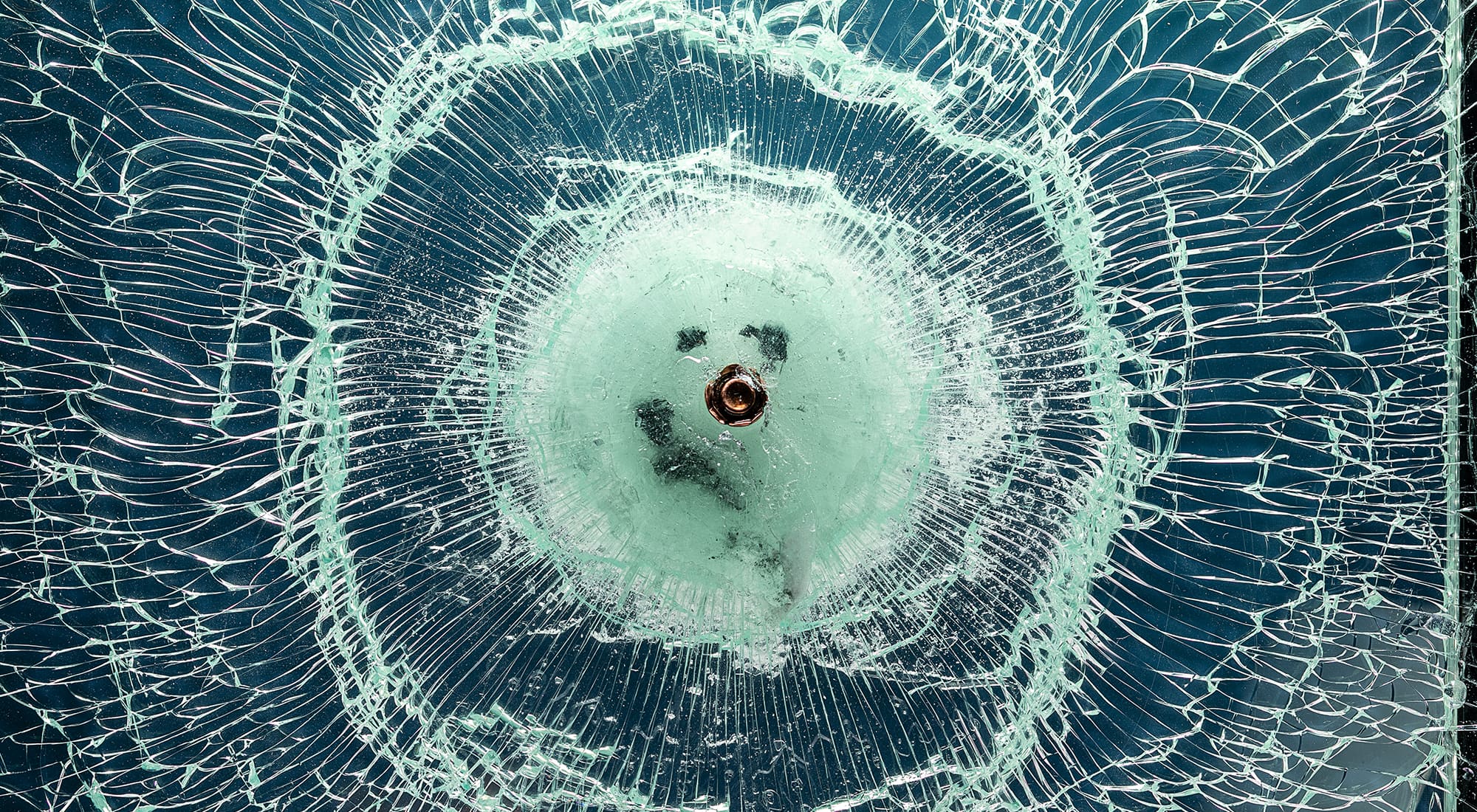

For many, the answer has been bulletproof glass products. Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles and is designed to stop bullets. It is usually made from a combination of two or more types of glass, one hard and one soft. Most bullet-resistant glass products are made of materials like polycarbonate, acrylic, or a polycarbonate layer retrofitted to existing, untreated glass.

Bulletproof glass has been a staple in high-security environments for decades, offering bullet resistance and robust protection against a bullet’s force and other ballistic threats. However, traditional bullet proof glass isn’t the only option available.

Another option available is bullet resistant glass laminates. Unlike bulky and conspicuous bulletproof glass, bulletproof glass laminates provide a discreet yet powerful barrier against attacks.

In this article, we’ll explore how traditional bulletproof glass is made and installed, its advantages and drawbacks. Then, we’ll dive into bullet resistant glass laminates, and highlight why they might be a better alternative.

Want to talk with our safety glass experts?

How Traditional BulletProof Glass is Made

Bulletproof glass, also known as ballistic glass or bullet resistant glass, is a durable glass material that is known for its thickness, protection, and its ability to withstand the force of projectiles. It’s made of a composite of several layers that work together to dissipate the kinetic energy of bullets and prevent glass shatter. This type of glass is essential for protecting high-risk environments.

Two of the most common bulletproof glass materials are glass-clad polycarbonate and laminated polycarbonate material.

Glass-clad polycarbonate combines the thick hardness of glass with the flexibility of a single layer of polycarbonate, making this material effective against a range of ballistic threats.

Laminated polycarbonate, on the other hand, has layers of polycarbonate and glass bonded together – offering a lighter and more flexible alternative while maintaining high levels of protection. Laminated polycarbonate is made by laminating multiple layers of polycarbonate sheets together with a polyurethane interlayer.

Manufacturing Glass Clad Polycarbonate

Typically, this solution starts with selecting high-quality glass and polycarbonate sheets. These materials are chosen for their separate and distinct properties: glass for its hardness and polycarbonate for its flexibility and impact resistance.

- Layering: Bonding multiple layers together is essential for absorbing the energy from even one single bullet and preventing it from penetrating through. The process involves alternating layers of glass and polycarbonate. The number of polycarbonate layers depends on the desired protection level. Typically, high-level ballistic protection will require more sheets to stop higher caliber bullets, rifle bullets, and multiple shots.

- Bonding: The layers are then bonded using special adhesives that improve the material’s ability to withstand impact. This bonding process is critical as it ensures that the layers work together seamlessly. The adhesives remain flexible, allowing the glass to absorb and dissipate the force of a bullet’s energy, preventing it from breaking through the glass to the other side.

- Heating and Cooling: The composite material undergoes heating and cooling after the layers are bonded. This step, known as autoclaving, helps to strengthen the bond. Autoclaving also helps to eliminate any air bubbles or imperfections on the glass.

- Testing: Rigorous testing is the last step. Bulletproof glass is tested using various firearms and projectiles to ensure it meets specific standards and protection capabilities. These tests measure the glass’s ability to stop a bullet’s ability to penetrate.

How is Traditional Bulletproof Glass Installed?

Installing bulletproof glass is a meticulous process that demands precision and expertise:

- Assessment and Preparation: First, the area where the bulletproof glass will be installed is assessed. The existing window frame or wall structure must be able to support the weight and bulkiness of the bulletproof glass, which is thicker and heavier than traditional glass. This includes measuring the dimensions, determining the appropriate thickness and type of glass required, considering the mounting factors, and determining other environmental factors.

- Framing: A sturdy frame is essential for holding the heavy glass in place. Often made from reinforced steel or aluminum, frames must be installed at precisely the right angle to fit securely and withstand the force of impact.

- Glass Installation: Due to the glass’ substantial weight, this step typically requires lifting equipment. The bulletproof glass will be carefully lifted into place, ensuring that it fits snugly into the frame. Then, the glass will be secured using high-strength adhesives and mechanical fasteners. The bonding process is critical to prevent any gaps or weaknesses that could compromise the glass’s integrity.

- Sealing: Once the glass is in place, it’s essential to seal the edges to protect against moisture and to ensure the glass remains firmly fixed. A layer of high-quality sealants prevents any potential leakage or damage.

Installing bullet proof glass is a meticulous process that demands precision and expertise

Proper installation is vital to ensure the protection of bullet proof glass. Any flaws or gaps can significantly reduce its safety capabilities. The glass must be perfectly aligned at the right angle and securely fastened to withstand the impact of bullets and other projectiles.

Challenges and Considerations of Traditional Bulletproof Glass Installation

Weight and Bulkiness

Bulletproof glass is significantly heavier and bulkier than regular glass due to the thickness (and weight) of the material. This requires reinforced frames, robust support structures, and specialized lifting equipment.

Specialized Equipment and Expertise

This type of thick and heavy glass can require specialized equipment. This includes lifting devices, like forklifts and scissors lifts, plus cutting tools and sealing equipment.

Trained professionals must oversee the installation to ensure that every step is executed correctly. This expertise ensures that the glass will perform as expected, stopping bullets and maintaining the safety of the building.

Key Takeaway: Installing bullet proof glass is a complex process that requires careful planning and execution. The challenges posed by its weight and bulkiness can be overcome with the right equipment and skilled installers. Proper installation is essential to maximize the protective benefits of bullet proof glass.

What Is an Alternative to Bullet Resistant Glass? Is there a Better, Modern Alternative?

Bullet resistant glass laminates offer a modern, effective alternative to traditional bulletproof glass. These laminates are composed of innovative and robust materials, such as polycarbonate and acrylic. They provide excellent protection while avoiding many of the drawbacks associated with conventional bulletproof glass.

Installation of Bullet Resistant Laminates

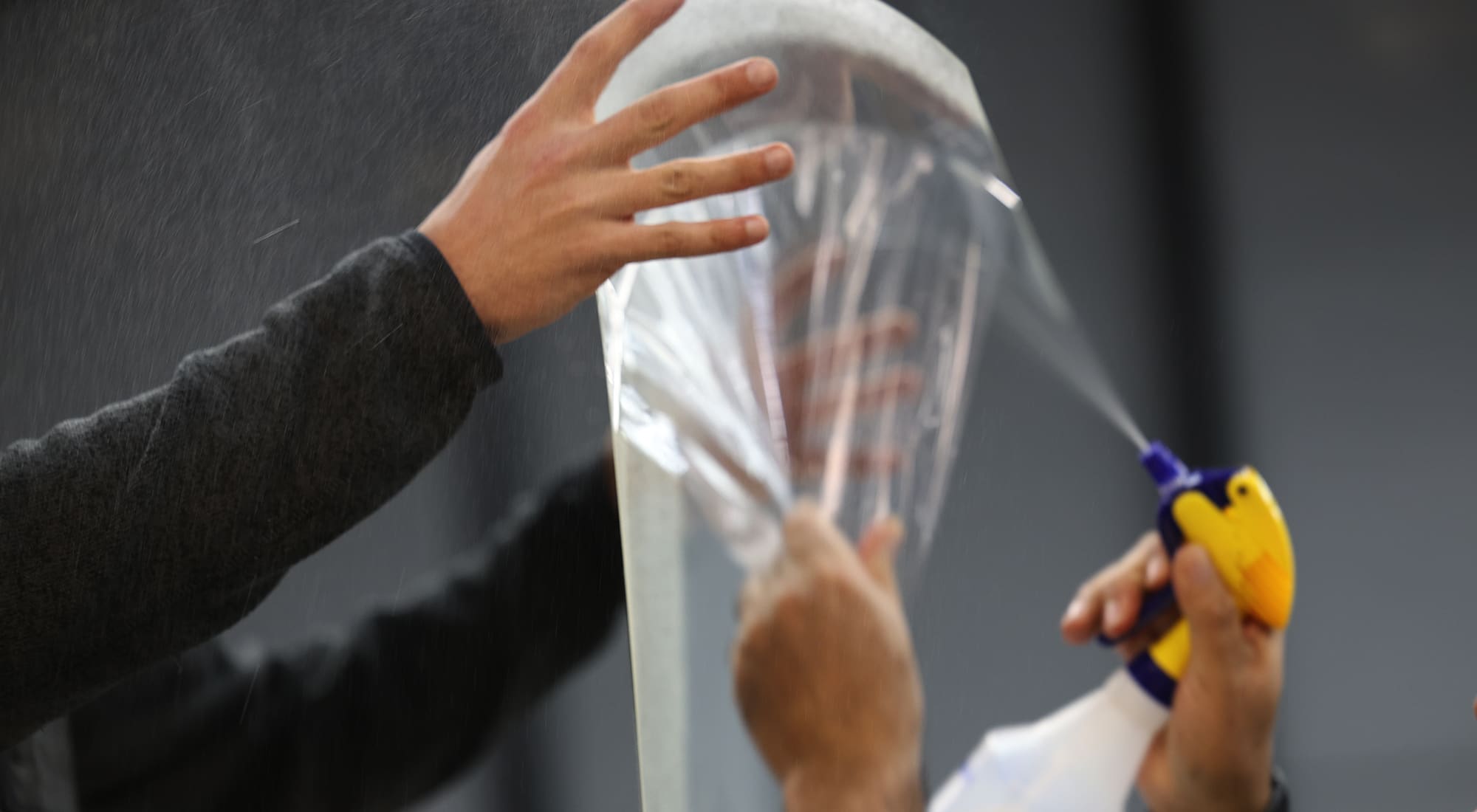

When it comes to installation, bullet resistant glass laminates offer a significant advantage over traditional bulletproof glass. The manufacturing and installation of security glass laminates are more cost-effective and less invasive, and they can be installed efficiently and without heavy-duty equipment.

Bulletproof glass laminate services start with a detailed site assessment, including measurements and evaluations of existing structures and glass. Once site measurements and preparations are made, the laminates are tailor-cut to size and applied directly to the existing glass surfaces. This process is more streamlined and affordable than bulletproof glass panels.

Another key advantage of bullet-resistant laminates is their discreet nature. Unlike the obvious, bulky presence of bulletproof glass, bullet resistant laminates blend in with the building’s existing windows and doors. They don’t alter the appearance of the building, making them ideal to maintain the aesthetic of the environment. Bulletproof security laminate installation is not time-consuming, so it will not disrupt your institution’s daily operations. There is no large, loud equipment to draw unwanted attention from visitors or staff.

Bullet proof laminate allows for customization based on the unique security concerns, size, and budget of the project. Whether a phased approach or a full-scale installation, laminates offer a cost-effective solution without compromising security.

Learn More: How to afford bulletproof glass laminate from Clear-Armor.

Effectiveness

Bullet resistant glass laminates are designed to withstand the impact of bullets and various projectile threats. They provide ballistic protection that is comparable to traditional bulletproof glass. The blend of polycarbonate and acrylic work together to absorb and disperse force, preventing penetration. This high level of resistance makes laminates suitable for various vulnerable environments, from schools and banks to government buildings and commercial properties.

Benefits of Discreet Bullet Resistant Laminates

Bulletproof glass laminates are made with optically clear, discreet material that offers a robust protection level.

Protective glass laminates will disrupt the attack cycle. Potential aggressors may not detect their presence, interrupting their plans and causing delays. This provides valuable time for authorities to arrive.

Bullet resistant glass laminates are versatile. They can be used in school buildings, banks, places of worship, and in commercial buildings. The ability to retrofit the laminate over existing windows and doors means that the installation causes minimal disruption at a fraction of the cost of traditional bulletproof glass.

Clear-Armor is the sole-source for a range of world-patented bullet resistant laminates. Our commitment to quality and customer satisfaction ensures you receive superior protection for your property. Whether you’re looking to secure a school, church, or workplace, bullet resistant laminates from Clear-Armor provide the perfect security solution for your glass doors and windows. Together, we can keep our communities safe.